The water treatment industry is increasingly demanding safe water. A clean and disinfected water supply is essential for the pharmaceutical, food, and cosmetic industries. Most pharmaceutical companies rely on UV systems for water disinfection. In the cosmetic industry, UV sterilization has become the preferred method. Specially designed wastewater UV systems disinfect sewage. As a result, many of the world's largest brands use ultraviolet sterilization to produce the highest quality products.

There are several advantages to UV technology. It is an effective way to disinfect water and remove inorganic and organic contaminants. It is also used in areas where conventional chlorine disinfection is ineffective. This process improves the taste, odour, and colour of water while requiring no toxic chemicals. It is a cost-effective way to treat water and meet environmental sustainability goals. To find out more, visit our Ultra Violet Filtration Plant Manufacturing website.

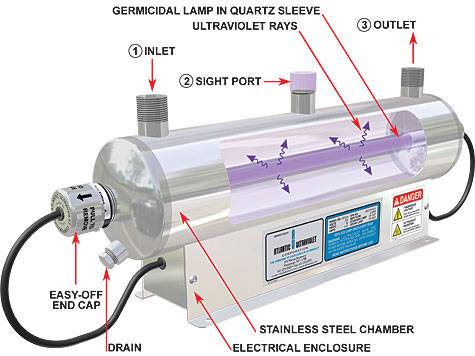

The UV lamp is the most important component of an Ultra Violet Filtration Plant Manufacturing company. This component gradually degrades over time due to continuous usage. It is important to periodically replace the UV lamp to ensure that the system continues to work as efficiently as possible. A UV water treatment system also has filters in its design, which accumulate particles as it runs. This means you have to clean and replace the filters regularly.

There are three main types of UV filtration plants: individual filters, combined filter effluent, and hybrid systems. Regardless of the type of ultraviolet filtration plant you choose, you'll need a reliable power source and a constant flow rate to operate it. You'll also need a UV reactor connected to a continuous power supply. In addition, each unit should have a WaterMark symbol or a similar standard to ensure proper operation.

The operating costs for a typical UV system are considerably lower than the operating costs of a conventional hypochlorite plant. Although the initial capital cost of a UV unit is more expensive than an equivalent hypochlorite system, the UV process is more efficient. It provides a return on investment in just a few years.

An ultraviolet disinfection unit can be of two different types. The first type uses ultraviolet light to clean water, and it has a low-flow capacity and is ideal for small and medium-sized facilities. It is designed to disinfect large volumes of water. Depending on the quality of the raw water, the wavelengths of UV light can be as low as 50 nanometers and as much as ten times lower.

Flow Range: 250 LPH to 20000 LPH

Materials: Stainless Steel (SS)

Operation: Semi - automatic / fully automatic plants

UV filtering plants are used to control chloramines in the water. It is crucial to choose an ultraviolet filtration system designed to treat the entire water flow through a pool's circulation system. When choosing a UV filtering system, its assumed transmittance should be 94% or higher, measured with a UV light of 254nm in a cell. A chlorine reduction system must be equipped with a medium-pressure lamp with a 200-320nm spectrum.

There are two types of UV disinfection: point-of-entry and in-line systems. There are two basic UV disinfection systems: in-line and point-of-entry UV filtration plants. The capacity of UV disinfection equipment varies from 0.5 to several hundred GPM. Particles and turbidity in the water can shield bacteria, so it may be necessary to perform pre-treatment to reduce turbidity. The maximum concentrations of bacteria or fungi for effective UV treatment.

When selecting a UV disinfection unit, it is important to consider your water quality and situation. Specifically, the clarity of the raw water will determine the amount of UV light transmitted. High turbidity water will need to be treated with pre-filtration and five- to twenty-micron filters. In the case of a low-turbidity water source, a UV disinfection device should handle this water without any further upstream modifications.